30 Years of Sawing in Wales with Five Wood-Mizer Sawmills

By Mareks Lomako, Wood-Mizer

David Jones from the small village of Rhosygwaliau near Bala was preparing himself for a completely different career. “After school I wanted to try something different from farming as we used to help my grandfather a lot on the family farm while growing up", said David. "I left the small village of Rhosygwaliau near Bala and trained as a chef in Eastbourne before returning home after 3 years and getting a job at Pale Hall Country house hotel where I worked up to head chef."

Two years later, David decided to return to his roots and to his native family farm. “A friend of mine saw a TV commercial of Wood-Mizer mobile sawmill,” said David. “He had 200 acres of woodland, and the idea of a sawmill seemed very attractive - you can clean the woods and cut old trunks. He bought an [Wood-Mizer] LT40 and asked me if I wanted to work with him. I always liked working with wood, so I gladly agreed.”

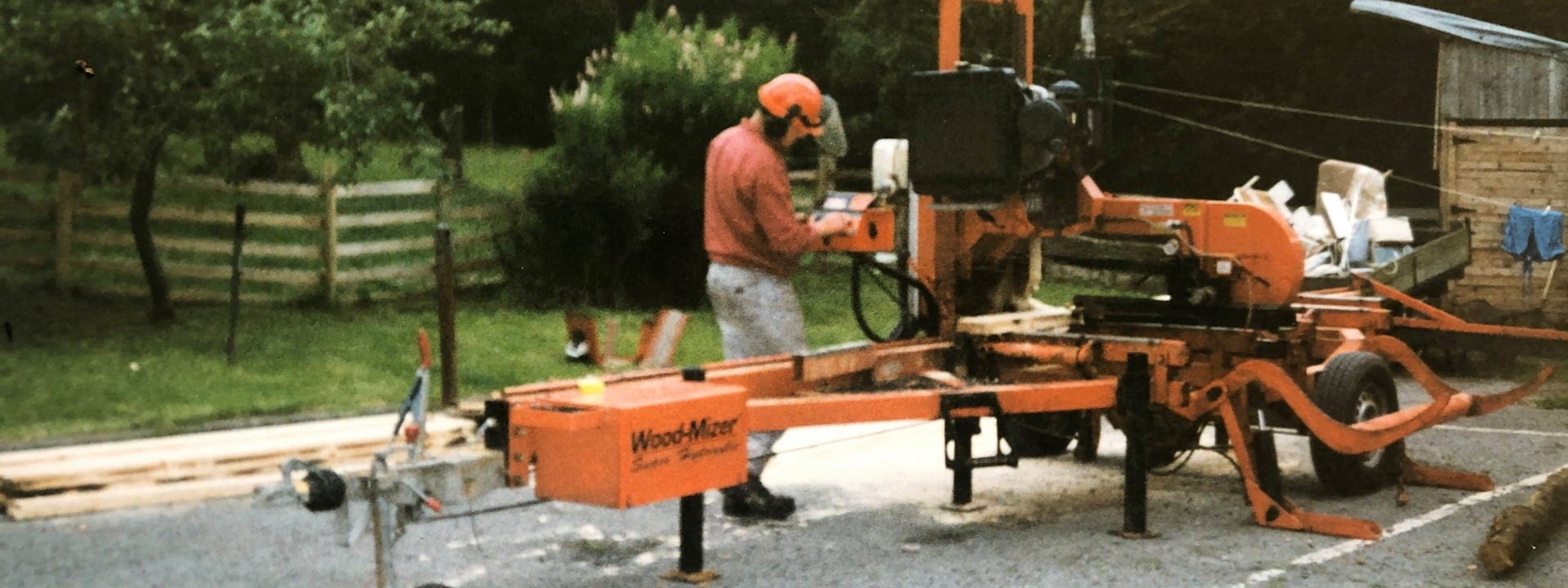

The former chef turned into a sawyer and the two friends began to travel in the area with a portable sawmill to provide custom wood sawing. After 6 years, David bought his own LT40 mobile sawmill.

“It was, I believe, in 1990,” recalls David. “So, yes, I’ve been working with a Wood-Mizer sawmill for more than 30 years.”

A Machine Made for Work

David is one of those professionals who thoroughly understands the intricacies of their business and knows their sawmill inside and out. “This is a fantastically practical machine,” said David. “It works in the rain, in the cold and in the heat. No weather can interfere with it. This machine is especially good when you need to fulfill sawing orders. It's very convenient - you can tow the sawmill anywhere and install it even in the woods, even on the farm. I really like this work. And of course, this machine is very good for making money.”

David has bought 4 Wood-Mizer sawmills already, always the LT40 model, and is preparing to purchase his fifth Wood-Mizer soon. It makes sense why David is selling his old sawmill because there is a great demand on the secondhand market and he is buying a new LT40 with a two-year manufacturer’s warranty. Although he gets the same LT40 model, there are new elements in the design, since Wood-Mizer is constantly improving the sawmill making it more convenient and easier to control. “I have had my last LT40 since 2008,” said David. “It worked for over 9,000 hours. It has a powerful 42 horsepower diesel engine and a full hydraulic system for loading logs.”

The LT40 narrow band sawmill is indeed one of the most popular Wood-Mizer sawmills in the world. This is due first to its efficiency, as a narrow band blade produces less sawdust and more lumber from each log, and secondly, with high quality cuts. Thanks to the cantilever head design, LT40 makes a perfectly accurate cut, even if it is setup on an uneven surface. Another advantage of the cantilever design is that the machine is capable of cutting large logs up to 90 cm in diameter. The LT40 model can be equipped with a gasoline, electric or diesel engine, and it is made so that an operator can work alone to tow the sawmill to the site, setup in 20 minutes, and operate independently starting with hydraulic controls to load logs. The Setworks digital processor quickly sets the head to the right position to cut the board of the required thickness, so the operator does not need to calculate and remember values in his mind. David says he had no problems with the LT40. "The sawmill is very reliable. If I need to change something - a bearing, hydraulic oil or something in an electric part - I usually manage it on my own in my garage. If I need some spare parts, I call the local Wood-Mizer representative and the next day I get everything I need by mail."

Wood-Mizer Blades

David uses DoubleHARD sawmill blades, also available from Wood-Mizer, with a 10/30 tooth profile. These are universal blades that successfully cut both hardwood and softwood. David sharpens them with Wood-Mizer blade sharpener using CBN borazon grinding wheel to perfectly reproduce the 10/30 profile and eliminate human errors. Recently, David learned about the new Wood-Mizer Vortex blades with a unique tooth profile. Vortex blades do not just saw wood, but also remove sawdust from the cut, resulting in a clean board surface that does not need to be further cleaned manually. “I haven’t tried them at work yet, but I’ve already heard about their ability to not only saw, but also to remove sawdust,” said David. “In my opinion, this is very convenient, especially if you need to stack oak planks for drying, there is always a lot of manual work, you need to brush them manually. I decided to try Vortex blades."

Fair Wind

At the moment David has many orders. He saws mainly Western red cedar (Thuja plicata) and makes cladding for construction. He currently fulfils a big contract for a local construction company in Bala.

“In general, the market is changing a lot,” said David. “People are increasingly looking to live in houses lined with red cedar.” A good market situation, like a fair wind, prompted David to buy another Wood-Mizer LT40. “I already had a very nice conversation with the bank manager, so, yes, this will be my fifth LT40 sawmill,” David smiles.

Best Way to Make Friends

When you live in a village where all the people know each other, a sawmill is the best way to have good relationships with neighbors. "This work is doubly enjoyable because you feel that you are not just cutting boards, but helping people to realize their plans, to make their dreams come true and to produce something useful out of wood that will last for many years."

The family tradition continues with one of David's sons studying carpentry in college. “I want to prepare a couple of stacks of boards from oak, chestnut and maybe walnut, and in 2 or 3 years, if my son wants to do woodworking, he will have a good supply of material to start,” said David. "In general, I have been sawing wood for thirty years, and I hope to do the same for the next thirty years.”