Massive Sawmill Upgrades a Family Business in Denmark

By Wood-Mizer, Europe

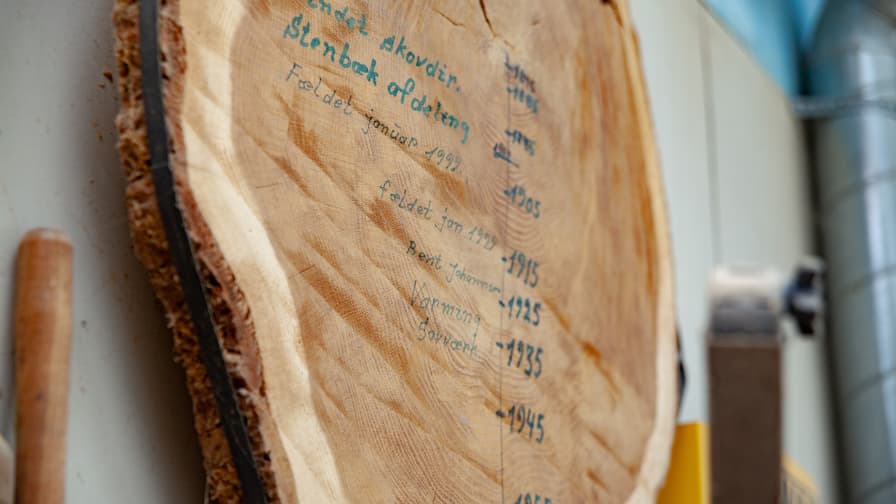

Thomas lautrup Andersen from Varming village in Denmark belongs to the third generation of a family that owns a local sawmill. “It all started in 1952 when my grandfather Bent Johannsen built a small carpentry workshop,” says Thomas. “Over time, it grew, and around 1965 the workshop converted into a sawmill.”

In the 70s, it was an active enterprise employing about 25 people. In 1988, Thomas’s uncle Stig Johannsen took over. “By 2002, grandparents had reached the age when they decided to sell part of the business. The sawmill was acquired by Leif Schmidt, who operated it as a hobby. My uncle Stig owned a carpentry shop at the time,” continues Thomas. “In 2014, Stig had a serious accident and had to hand over the family business to me. In 2017, I repurchased the sawmill from Leif, who had once bought it from my grandfather.”

Today the Varming Sawmill is a combination of a sawmill, joinery, and carpentry business to tackle almost any timber project. “My motto is we can make anything out of wood,” says Thomas. “It can be a small project - replace one board, or maybe cover the entire roof - we can do both with the same respect for quality. Windows, doors, floors and ceilings, installation work - we do a good job that pleases both the client and us.”

The website www.varming-savvaerk.dk displays examples of completed projects, from fences to wine shelves and cherrywood dressers.

Although many woodworking machines have been acquired at the sawmill over the years, at the heart of operations is the Wood-Mizer LT40 band sawmill, which Thomas purchased in 2015.

“I still have the feeling as if I only started working yesterday,” Thomas shares. “I hadn’t heard anything about Wood-Mizer. I was new to the business.”

Wood-Mizer sawmills operate all over Denmark. “It’s great that you can go and see how they work,” says Thomas.

“In the beginning, I just tried working with the [Wood-Mizer] machine. It turned out well. I was able to make a profit and saw how easy it is to operate this machine.”

“I spend about half of my time with clients, doing carpentry work, and the other half here in the workshop, working on my sawmill and making a variety of wood products.”

The LT40 sawmill can cut logs up to 90 cm in diameter and 6.5 m in length. When Thomas needed to cut even larger diameter logs, he turned to Wood-Mizer again. “I thought Wood-Mizer had the right machine. And I bought my second Wood-Mizer sawmill, a WM1000” says Thomas.

The WM1000 main feature is that the sawmill can cut extra wide logs up to 1.7 meters in diameter. The sawmill uses narrowband blades that make a thin-kerf about 2 mm thick so that you can produce more boards from every log, and less wood turns into sawdust. The WM1000 sawmill can make wide slabs and blocks from large logs, which is valuable, for example, when you need to cut out worktops or benches for garden furniture from solid wood.

“With this machine, I can cut any log,” says Thomas. “I have new clients all over Denmark. After all, few people can saw such large logs.”

The WM1000 design includes a massive saw head that moves along two rails. The operator stands on a platform that travels with the saw head. There is a control panel with a Setworks for automatically setting the board thickness on the platform, so the operator has a good view of every cut from here and makes the right decisions about how best to cut the log to get the most beautiful board surface and the highest yield.

“I didn’t expect such a massive machine to be so fast,” says Thomas. “I cut pine and oak logs. Of course, I try to use every piece of wood to get as much product as possible. With the WM1000, this is possible because it makes a very accurate cut.”

The WM1000 installation in the old workshop was inexpensive and straightforward, as it only requires two rails to be installed.

“With this machine, I can handle any order to cut logs,” says Thomas. “That’s why I bought WM1000”.

More info: www.varming-savvaerk.dk