How to Choose the Best Wood-Mizer TOOLS

Wood-Mizer started offering TOOLS in 2016. With Wood-Mizer cutting tools, woodworkers operating planers/moulders, multirips, or other equipment will produce the highest quality of products while working comfortably and safely. The wood cutting tools are produced from top-quality materials and with advanced manufacturing technologies. Each production stage is subject to strict quality control ensured by high-tech measuring devices in the manufacturing process.

"The products from the TOOLS catalog are known for their extreme durability and increased lifetime compared to similar products of competitive brands," says Jarosław Urbański, Product Manager of Wood-Mizer TOOLS. "For us, the most important is quality and safety at work, and therefore we pay attention to the quality of raw materials to produce these tools. For example, the Wood-Mizer circular saw blades are top-quality steel with premium carbide inserts, and these blades are proven globally for the highest cutting performance."

"Customers choose Wood-Mizer TOOLS because these tools guarantee the highest quality of finished materials. They remain sharp longer and allow the operator to save time resharpening and installing on the machine. In production, a sharp tool also means less friction during cutting and less power consumed by the electric motor," points out Jarosław Urbański.

To produce tools, Wood-Mizer uses steel from trusted and reliable European factories, e.g. for the frame saw blades production, Wood-Mizer utilizes the Swedish Uddenholm steel or the German Krupp steel confirmed by quality certificates. These tools exceed other competitive products imported from Asia by higher durability and precision. "Our clients accept the TOOLS price realizing how much they benefit from them," explains Jarosław Urbański.

Wood-Mizer also uses advanced technologies for tools production. The circular saw blades are subject to a special thermal and chemical treatment process to strengthen the blade body. The blade with a black body generates less friction while preventing the woodchips and sawdust from sticking to the blade. In addition, the strengthening of the blades improves their stability at work and prevents overheating resulting in longer operating time and higher quality of final products.

Wood-Mizer cutting TOOLS uses carbide with a carefully selected chemical composition, resulting in proper hardness, abrasion, and resilience qualities. For the circular saw blades, it's also essential to choose the appropriate tooth geometry. The Wood-Mizer TOOLS provide longer worktime between resharpenings, a more significant amount of processed wood, or a higher number of possible resharpenings per single tool.

Machines Compatible with Wood-Mizer TOOLS

Wood-Mizer introduced the TOOLS series while it launched a new Wood-Mizer board edger to the market. The EG300 is a multirip edger with circular saw blades available from the TOOLS catalog.

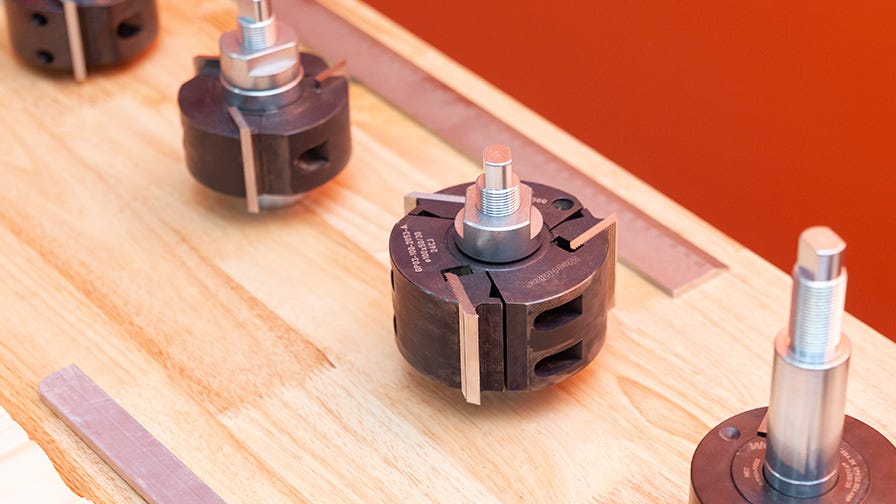

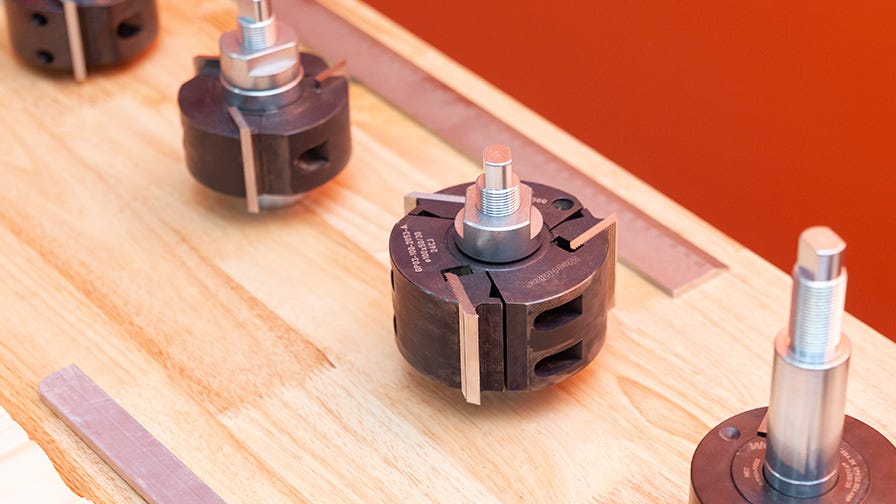

The range of tools had expanded considerably when the Wood-Mizer introduced Woodworking machines with the cutterheads and cutting knives also available from the TOOLS range. Wood-Mizer multi-head planer/moulders can produce a final product after just one pass through the machine. The operator has a wide choice of straight HSS, HM, and coated knives with an extended lifetime and a range of moulding knives.

Wood-Mizer machines equipped with the TOOLS cutting products include:

• Edgers and multirips EG100, EG250, EG300, EG350, and the double arbor multirip MR200

• Log moulders MP100 and MP150

• Woodworking machines MP365, MP360, MP260, MP220, MP200, MP180, MP160

• Table saw MS300 and the vertical spindle moulder MF130

• SlabMizer MB200 for flattening large surface slabs

The Wood-Mizer TOOLS are also popular among the users of other machine brands since they are manufactured according to the EU standards and are compliant with the standardized machine system used across the machines of different brands.

TOOLS Application

The TOOLS cutting equipment is designed to process solid hardwood and softwood, glued wood and wood-based materials, plywood, chipboard, laminated boards, MDF and HDF boards, and other hard homogenous materials. The TOOLS catalog also includes the saw blades used in Lucas and Peterson sawmill machines.

The second-largest group of TOOLS cutting equipment is the selection of woodworking cutterheads and knives used in Wood-Mizer planer/moulders. The knives are offered as straight, serrated back knives, HS and HW planer knives, and profile knives. The wide selection of knives is able to produce any shape and dimension of woodworking product.

One more group of Wood-Mizer TOOLS products is a range of through drills, Dowell drills, and boring cylinder drills. They are offered as monolithic HM drills, tipped drills, or soldered drills.

The last group of TOOLS accessories is a range of frame sawmill blades designed for vertical sawmilling. These blades are manufactured from high-grade Uddenholm or Krupp steel and are characterized by improved durability and resistance. The offer includes frame saw blades for spring setting, chromium-coated saw blades, and Stellite saw blades.

How to Choose and Order Wood-Mizer TOOLS

For a quick and easy selection of cutting tools, all products in the Wood-Mizer TOOLS catalog are marked clearly according to international standards. On the instrument and the packaging, there is the Wood-Mizer logo, which proves that the product is original. Apart from that, a letter symbol denotes the tool's application and its technical parameters – outside and inside diameter, the number of teeth, carbide width, blade thickness, and the number of raker teeth. To help customers reorder the TOOLS products quickly and effortlessly, Wood-Mizer TOOLS are marked with a unique item number identical on the box, on the product, in the catalog, and on the company Intranet.

To get the Wood-Mizer TOOLS catalog, you need to contact your local Wood-Mizer sales office. Additionally to the TOOLS selection, customers can find a piece of tremendous practical information about the marking tools, application of tools, tables, technical drawings, and product photos in the catalog. The TOOLS catalog helps you order the products according to individual needs and requirements. Some specialized tables and formulas may help select cutting parameters for different applications. Ordering moulding and profiling knives are also possible in the e-store https://woodmizer.eu/blades-and-knives where the range of TOOLS is being continuously developed and updated.

The selection of TOOLS is not limited only to the specifications listed in the catalog or on the internet website. "Our specialists are ready to advise customers in making an order for a special tool. Manufacturing a special tool always complies with appropriate norms and standards to ensure the highest quality of the tool and safety work," points out Jarosław Urbański.

Working with the Cutting TOOLS

Even though the best idea for the customer is to use the TOOLS on a compatible Wood-Mizer machine, we highly recommend using them as well on other machines available on the market. Mounting the cutting tools on a Wood-Mizer machine has been made easy and requires little time.

The Wood-Mizer cutting TOOLS are suitable for resharpening on various grinding machines available on the market. Resharpening in a specialized workshop would be the best option for customers who do not have much experience. "A great benefit for the customers is a longer lifetime of Wood-Mizer TOOLS, which means they do not need to resharpen them too often. These tools remain sharp longer and help increase work efficiency," says Jarosław Urbański.

Wood-Mizer supplies a 2-year warranty for TOOLS products and standard technical support for the original machines. "Before sending the order for a new TOOLS product, we suggest contacting Customer Service or Sales departments. Our experts are willing to assist in choosing the right cutting parameters for the desired operation, which will improve the efficiency and precision of work," points out Jarosław Urbański.

***