How to Service a Sawmill

By Wood-Mizer, Europe

Wood-Mizer sawmill owners are interested in the efficiency of sawing. In order to maximize the sawing time, you need to do regular maintenance and replace spare parts, so that you could avoid unnecessary breaks at work. Following the advice below, will help provide longer run-times and better sawing quality of your sawmill.

1. Check the condition of the chains responsible for forward/reverse and up/down movement of the head:

- clean the chains from sawdust and dirt,

- inspect the tension and if necessary make the adjustment,

- remember to grease the appropriate parts,

- if you notice a broken link or pin, immediately replace the faulty section or the whole chain with a new one.

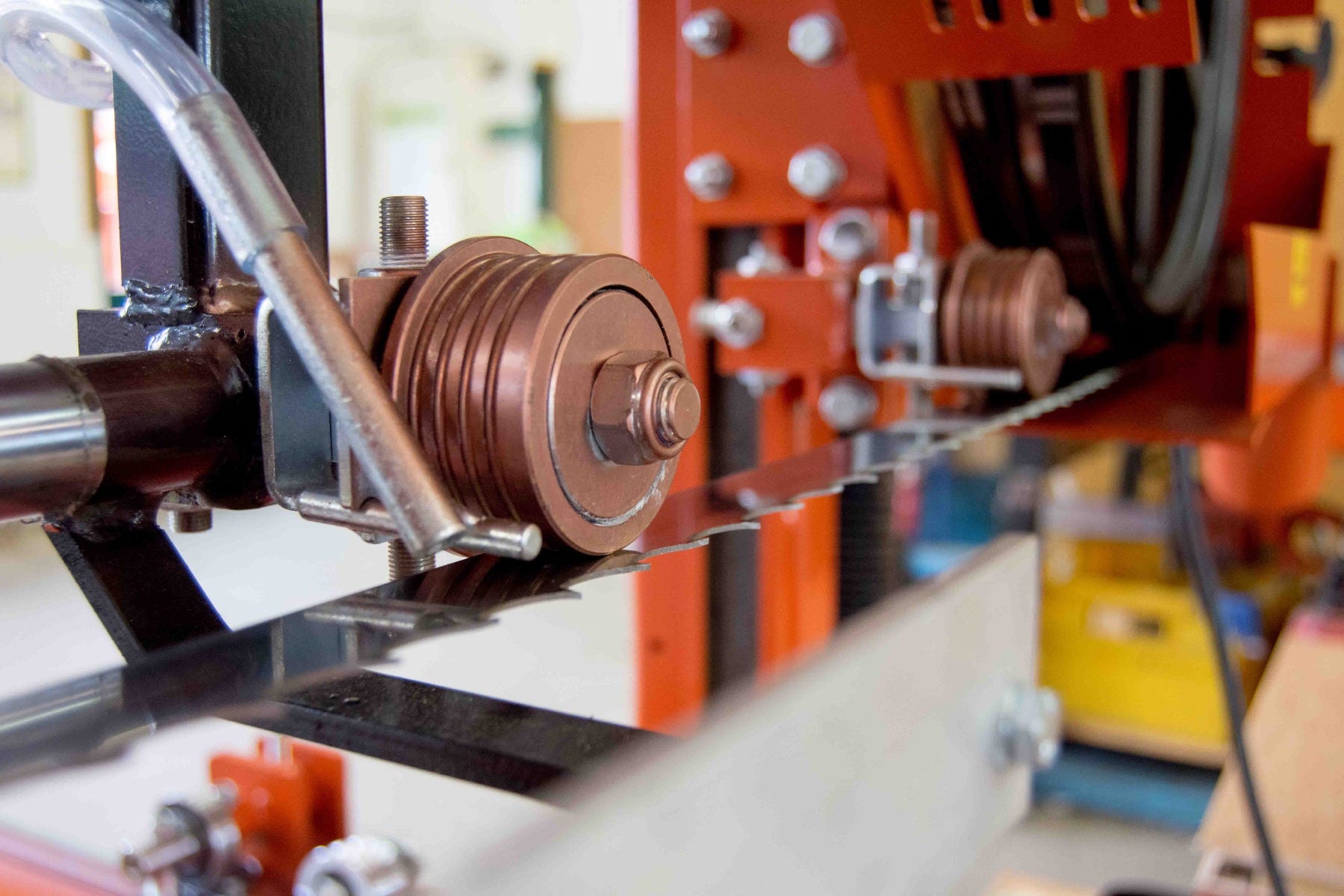

2. Adjust the blade guide rollers:

- check the deflection of the blade guide rollers on the blade (depending on the sawmill model, it should be 4-6 mm; for more information please refer to the user’s manual, chapter: Settings),

- using the measuring device called the straight edge blade alignment tool (available as a standard tool while purchasing the sawmill), check the alignment of the blade against the sawmill bed,

- check the overall condition of rollers, wear of collar, depth of grooves and the condition of bearings,

- if you notice any scratches on the surface of rollers or when they are irregular in shape, replace the rollers.

3. Check the condition and the tension of drive belts, and adjust the tension or replace them with new belts if necessary.

4. Look closely at the rod shield found on the main frame. Check if the felt placed inside is sufficiently greased and if the condition of plastic sawdust scrapers on the main rod allows the machine to work properly.

5. Check the oil level regularly and the condition of the filter in the hydraulic system (we recommend to replace the filter every 600 hours of sawmilling). Don’t forget about inspecting the positive connector, and make the adjustments or replace it if necessary.

6. If your sawmill has a battery check the battery, check its charging level regularly, as well as the tension of the alternator belt and the condition of carbon brushes in the DC motors.

7. Grease systematically and check the condition of the drum switch connectors controlling the head movement forward/reverse/up/down.