Why Do Sawmill Blades Break?

By Wood-Mizer, Europe

To increase sawmill blade life, there are eight significant reasons for premature sawmill blade rupture to look out for when operating a sawmill.

How many hours does a bandsaw blade have, or how many cubic meters can it cut before needing to sharpen or replace? The answer to the question "How long does a sawmill blade last?" depends on the blade quality and many more factors. In this article, you can learn what you need to pay attention to when working on a band sawmill to avoid premature blade breaks and increase blade life.

Sawmill blade manufacturers do not indicate the exact number of hours or cubic meters the blade should cut. The fact is that there are too many factors affecting the blade condition, which are not under the manufacturers' control. For example, Wood-Mizer is in charge of the sawmill blades manufacturing process and ensures that it produces the blades from quality steel alloys. Wood-Mizer operates state-of-the-art equipment for profile making, hardening, sharpening, setting, and welding blades.

In addition to quality, bandsaw blade life also depends on the following factors:

- The sawmill blade maintenance: how you sharpen the blade and set teeth.

- The sawmill: what sawmill you operate, how it’s adjusted, and if the blade is correctly aligned on the mill.

- The wood: are the logs clean? Are there metal inclusions in the logs? Does the sawmill have a debarker?

- The feed speed: the moment the saw blade enters the wood is especially important.

Let's take a closer look at the causes of premature bandsaw blade failure.

Reason 1. The blade has been in operation for too long.

When operating a band sawmill, a general rule is to replace the bandsaw blade with a sharpened one on average every 1,5 hours of cutting. In the case of cutting dirty wood, this time will be shorter.

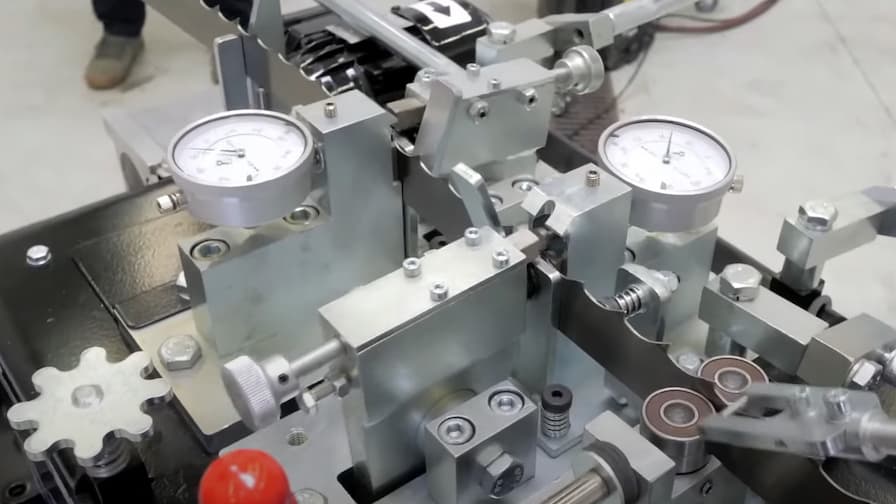

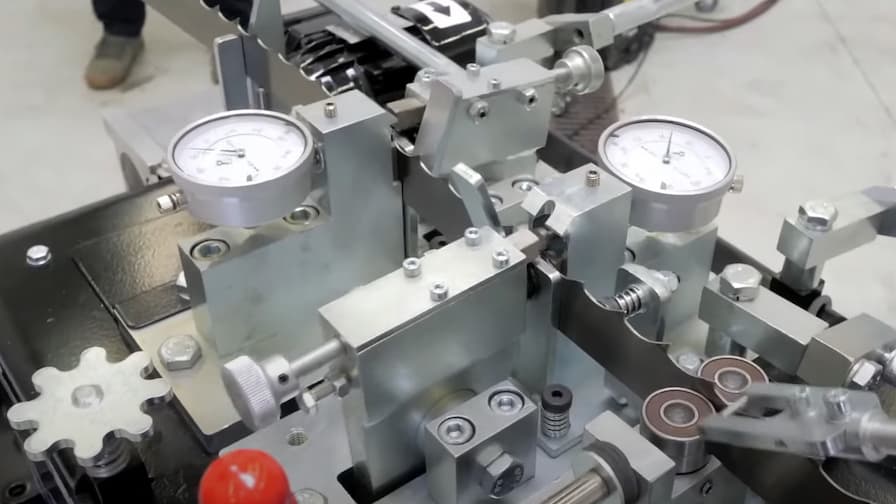

Reason 2. The blade guide rollers are worn out.

The blade guide rollers ensure the correct position of the saw blade relative to the sawmill bed and the blade stability in the kerf. They are also responsible for the correct tension of the blade. It is essential that the rollers are in good condition without any traces of wear, such as deformation (cone shape), damaged bearings, worn-out roller flange. Worn rollers cause the sawblade vibration and unstable work in the wood, which will lead eventually to a breakage. If the rollers are worn out, replace them.

Reason 3. The wheel belts are worn out and too thin.

Use genuine Wood-Mizer pulley belts that have a unique form. Wood-Mizer's patented blade wheel belts keep the blade out of contact with the pulley's metal, resulting in increasing blade life. Also, with the belts, Wood-Mizer wheels never need to be straightened or crowned.

If the blade wheel belts are worn out, the blade could contact the wheel, causing the blade to break. It is essential to check the belts' condition regularly. The layering of their surface is unacceptable, and they should also not be excessively dirty with collecting sawdust. Usually, both belts are replaced at the same time.

In addition, to ensure uniform wear of the belts, it is recommended to swap them from time to time on the drive and idle pulleys.

Reason 4. The blade guide rollers are incorrectly aligned.

The adjustment of the rollers is checked with the adjustment ruler included in the sawmill tool kit. The gap between the rear edge of the blade and the roller flanges must be at least 3-4 mm and equal for both rollers. Rollers should create some tension and press the blade downwards 6 mm. Read more about this adjustment in the article "How to Adjust Blade Guide Rollers"

Reason 5. Check the position of the blade on the blade wheels.

Adjusting the idle pulley is usually straightforward, and it is described in detail in the user manual. A more complex operation is adjusting the blade wheel on the drive side. Make sure that after adjusting both blade wheels, the sawblade extends from the wheels equally (average 3-4 mm between the sawblade gullet and the blade wheel rim). If you have questions about blade wheel adjustment, please consult a technician at your Wood-Mizer service center.

Reason 6. The bandsaw blade is dull.

How do you know when a bandsaw blade is dull? If the blade is dull, the tension constantly drops during operation and makes the sawblade wave in the wood. You cannot solve the problem simply by increasing the blade tension above the recommended value indicated on the sticker on the saw head. It may help but only for a while. For the sawblade to be always correctly sharpened, you need to check regularly the condition of the CBN grinding wheel, replace the oil in the sharpener, and in case of a dirty grinding wheel, cleanse it with a solvent.

Why is the bandsaw blade blunt?

The blade has been running continuously for more than 1,5 hours.

The logs are covered with bark and dirt. Sometimes it is enough to cut only 15-20 cm of such a log to make the blade dull. When sawing dirty logs, you need to manually clean the bark before sawing or use a debarker – an option on most Wood-Mizer sawmills. A debarker is a circular blade that removes a thin strip of bark directly in the place where the sawmill blade enters the wood.

The blade can also encounter metal objects in the wood, including nails, bullets from wartime, etc. In this case, you should replace the blade for further sharpening and check the blade guide rollers' alignment.

Reason 7. Aggressive blade feed.

If all of the above on your sawmill is in order, pay attention to the sawing technique. Operators may be sawing too fast trying to exceed targets resulting in blade overload and product quality decrease. Working with aggressive blade feed will result in sawblade overload and “waving” of the blade when it enters the wood. In this case, the intense signs of contact with the rear edge of the sawblade will be seen on the flanges of blade guide rollers.

If, after the blade enters the wood, the blade "dives" and you get a wavy surface of the board, we recommend you read the article "How to Avoid 'Wavy' Cuts"

The blade is also overloaded if its teeth profile and set do not correspond to the type of wood.

Reason 8. Errors in the sharpening and setting of the bandsaw blade.

This is the most common reason for premature blade breaks.

The good news is that modern sharpening equipment uses the CBN grinding technology with a CBN wheel with a blade tooth profile. Using CBN wheels means that the quality of sharpening is less dependent on human errors. Here you can find Wood-Mizer's tips for sharpening bandsaw blades and an overview of Wood-Mizer sharpeners of different price categories, which differ primarily in performance. All these sharpeners provide high-quality regular saw teeth sharpening.

Sharpening is needed to sharpen the cutting edge and remove numerous microcracks that have formed in blade gullets. During sawing, these microcracks grow, causing the blade to break.

Wood-Mizer recommends removing 0.10-0.15 mm of metal in one sharpening cycle.

If the saw blade has been used in hard conditions (dirty logs or frozen logs), the sharpening depth should be increased, or the cycle should be repeated 2-3 times so that the microcracks are removed completely. It’s essential to control the pressure of the CBN wheel and the quality of cleansing it with the mineral oil, in order to avoid burning of teeth.

If the blade teeth burn out during sharpening, the edge becomes very fragile at the burned area. In such a place, deep microcracks appear, which, when sawing, lead to the blade breaking.

The reasons for metal burning out are as follows:

- Too intense pressure of the grinding wheel during sharpening.

- The use of a CBN wheel of a wrong profile. In this case, a particular part of the tooth profile edge is not ground, while another section is sharpened too aggressively. In this area, the saw blade is burned out, and subsequently, deep microcracks form, which will lead to the blade break, even if it is an almost new blade that has only gone through a few sharpenings.

Wood-Mizer sharpeners have adjustment functions allowing for the correct positioning of the sawblade against the grinding wheel. For every sharpener and tooth setter made by Wood-Mizer, free user training is offered.

After the sharpening, check the result (tooth profile) using a new blade as a reference. If the blade is sharpened correctly,

- the tooth profile is correct,

- the height of all teeth is the same,

- there are no traces of metal burnout,

- the metal burrs are entirely removed,

Here you will find Wood-Mizer tips for setting bandsaw blades and an overview of tooth setters.

Six common mistakes when sharpening and setting sawmill blades

1. Sharpening the sawblade using the wrong profile of the CBN grinding wheel. Incorrect geometry will make the sawblade blunt too quickly and the grinding wheel will wear too quickly, as well.

2. The clamping on the sharpener isn’t aligned with the grinding wheel. In effect, the uneven height of the teeth will make the sawblade wave in the wood.

3. If the grinding wheel is too dirty, with clogged pores, it will result in metal burning, too quick wearing out, and waving of the sawblade.

4. If the grinding wheel is worn out, the sharpening process will be ineffective and it will not remove all microcracks.

5. Uneven tooth set, which means that there’s a discrepancy between the left and right sides. It will make the sawblade wave in the wood.

6. The setting point of the tooth is too high up. It’ll cause a poor quality of cutting, waving of the blade in the material, as well as a premature breakage. The sawblade will vibrate during cutting. The correct setpoint should be placed at 1/3 of the tooth height.

Here you can get ten tips on "How to Increase a Sawmill Blade Life"

Tip: Use quality blades - it pays off

People say 90% of sawing success depends on the sawmill blade. However, since this is a consumable tool - the blades become narrower during operation and break - many sawmill owners seek to reduce the cost of purchasing blades by choosing the cheapest ones resulting in poor quality blades.

You need to understand that even if a blade is more expensive than others, this does not mean that the blade cost in terms of sawn volume per one blade will be higher. On the contrary, with a better quality blade, you will cut more timber than with cheaper ones, and as a result, a more expensive blade will be more profitable and save on costs.

Somewhere between costly specialized blades designed for hard-to-work wood and very cheap blades with the only advantage in their price, there is a middle ground - quality blades at an affordable price that are right for your purposes.

How to choose a sawmill blade

Wood-Mizer is one of the few sawmill manufacturers that also produces sawmill blades. Wood-Mizer has developed the 10/30 universal tooth profile that is recognized as the benchmark in sawmilling - many blade makers call it the "Wood-Mizer profile."

Today Wood-Mizer produces several series of bandsaw blades that differ primarily in the steel alloys of which the saw blades are made. With a range of combinations of tooth profiles, thicknesses, and lengths, Wood-Mizer has over 100 bandsaw blade options to choose from for the best result for both price and quality cutting. Read more in the review "How to Select a Sawmill Blade Type".

Wood-Mizer's European manufacturing center produces hundreds of thousands of meters of band sawmill blades per year. It is a modern production facility certified according to ISO 9001: 2015 quality standards. Here you can learn more about Wood-Mizer blade production.

Please note that Wood-Mizer offers ready band sawmill blades in any custom length.

Wood-Mizer wishes you successful sawing and significant cost savings!

Sign up for the Wood-Mizer e-newsletter and receive your free eBook "How to Improve Your Bandsaw Performance“.