Wood-Mizer Bandsaw Blade Sharpeners - The Ultimate Tools for Sawmill Blade Maintenance

It’s no secret that every sawmill blade needs proper maintenance to cut with efficiency and precision. In the process of sawmilling, even the best blade will get dull sooner or later, with its edges reducing the ability to cut effectively and the gullet losing its correct shape. There is a way to improve that – you need to sharpen your blades using a specialized machine, a grinding wheel, and mineral oil for grinding. After sharpening, you need to set the blade teeth to prepare the sawmill blade for cutting.

Wood-Mizer has always recommended using Wood-Mizer sawmill blades, which guarantee the best performance and high durability, at reasonable prices. Alongside Wood-Mizer blades, sawmillers are advised to choose from a range of machines and accessories for maintaining the sawmill blades on their own, for example, bandsaw blade sharpeners, tooth setters, set gauges, CBN wheels, and grinding oil.

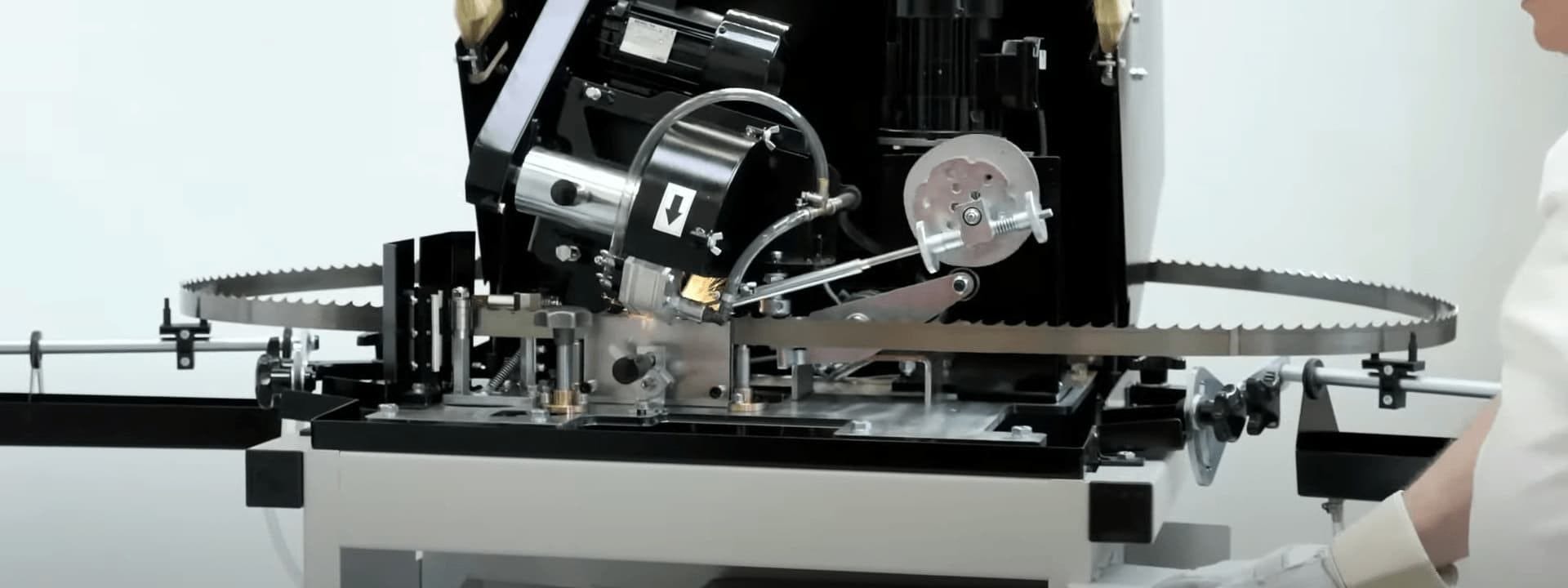

One of the essential tools for sawmill blade maintenance is a sharpener, which will restore the blade’s sharp edges and its correct tooth profile. Wood-Mizer has several bandsaw blade sharpeners in its offering – an affordable BMS250 and a more advanced BMS500 or BMS600. Even though they have a different design, they share some common characteristics – all of them use profiled CBN grinding wheels and have the grinding head locked at an angle, securing the best match and consistency of the wheel with the blade profile.

CBN grinding technology

Wood-Mizer recommends using CBN grinding technology, which employs a super abrasive material, a cubic form of boron nitride, for the best sharpening results. CBN grains are as tough as the earth’s hardest material - the diamond. They perform in grinding much better than the conventional aluminum oxide or silicon carbide grinding wheels, as they don’t get dull quickly and don’t burnish the material. Since a CBN wheel has a profile, it must match exactly the geometry of the blade tooth. Wood-Mizer offers sawmill blades in a dozen different tooth profiles, and for each blade profile, there’s a dedicated CBN profile. Disrespecting this rule will cause damage to the grinding wheel, deformation of the blade profile, or even breakage of the grinding head in the sharpener.

CBN grinding technology needs mineral oil for cooling and cleansing. Wood-Mizer recommends using the mineral oil of ACP1 or ACP2 technical specification to effectively cleanse the delicate abrasive structure of the wheel and cool down the surfaces which heat up in the process of grinding. Following these recommendations will help to use the CBN grinding wheel for a long time, with the best performance in operation.

Best Sharpeners for Improved Grinding Performance

The range of Wood-Mizer bandsaw blade sharpeners begins with the BMS250, a high-quality, automatic sharpener designed for regular and reliable blade maintenance in a professional timber-production business. The BMS250, contrary to its simpler version – the BMS200, features a grinding headcover protecting the inside mechanism and a control panel integrated with the electric box. The sharpener is driven by a 0,18 kW (230V) electric motor, spinning the 127-mm grinding wheel to 2700 rpm. It sharpens 25-50 mm wide sawmill blades as efficiently as possible thanks to such features as an auto-shutoff, variable feed rate, exhaust vent, and oil wiper pads. Installation of the blade on the machine and the procedure of grinding depth and pusher movement adjustment are straightforward and effortless. Wood-Mizer recommends running the sawmill blades through the machine in 2-3 cycles for the best sharpening results, which generally take less than 4-5 minutes.

Two more sharpeners from the Wood-Mizer offering are the BMS500 and the BMS600. Their design meets the requirements of high-production sawmills that sharpen blades continuously. The BMS600 is similar in design, featuring only a more efficient oil pump, a larger oil tank, and upgraded oil-application nozzles. Both models are compatible with a 203 mm grinding wheel, and they are powered by a 0,75 kW (400V) electric motor, working at 4280 pm. For improved efficiency of sharpening, the BMS500 and BMS600 have an automatic deburring tool, auto-shutoff with the teeth counter, and an easy-to-access control panel. Sharpening a 25-75 mm wide sawmill blade with the tooth spacing of 13-29 mm, generally takes a 3-4 minute single cycle.

Sawmill Blade Sharpening Tips and Advice

It’s important to remember a few general rules of sharpening sawmill blades and maintaining the sharpener. Before starting any blade maintenance, make sure you’ve prepared the sawmill blade and the machine for it. Follow these recommendations as well:

1. Sharpen blades that have been cleaned from resin, sap, oil or dirt, so that the process is as effective as possible and won’t put any additional wear-and-tear on the machine.

2. Adjust the depth of grinding and the pusher movement before each cycle of sharpening. Otherwise, the blade will not perform well during sawmilling.

3. Use CBN wheels with the profile matching the geometry of the blade. Do not try to change the angle of the grinding head set by default in the factory. Maintain the CBN wheel by cleansing it regularly with a brush and solvent.

4. Use the mineral grinding oil of technical specification ACP-1 or ACP-2 to cool down the blades and prevent the CBN abrasive structure from clogging. Replace it regularly and use the exhaust to avoid inhaling the grinding fumes.

5. Inspect the blade clamps of the sharpener, check the condition of the pusher advancing the blade, clean the oil-application nozzles, remove metal filings from the magnets dipped in the oil, check and replace any movable parts of the machine on time.

6. Store your sharpener in a clean and dry environment. Remove dirt, sawdust, wood chips, and other debris at the end of the work shift.

7. “Safety First” – Do not disregard wearing gloves for handling sharp objects, safety glasses for protecting your eyes, and earplugs for blocking harmful noise. Read user manuals and follow the instructions provided by the manufacturer.

Following these tips and recommendations will guarantee a long and satisfactory operation of the Wood-Mizer bandsaw blade sharpeners and will help to maintain the sawmill blades on a high level.

Get a Free Ebook

Find out how to improve your blade performance and extend blades lifetime. Subscribe to our newsletter and get an ebook covering the ten most important topics on bandsaw blades and links to useful videos.

***